Racing Wheel Sizing Guide

Measuring Racing Wheels

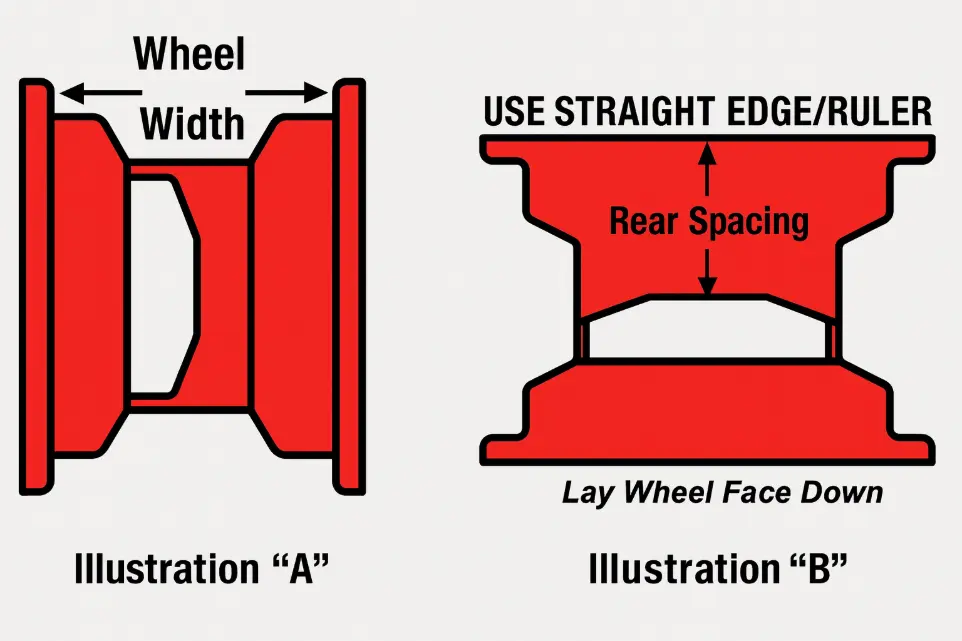

Measuring Wheel Width (Illustration “A”)

1. Lay the wheel on its side

Place the wheel on a flat, stable surface with the face of the wheel pointing upward so you can clearly see the cross-section.

2. Identify the inner bead seats

Wheel width is measured between the inside bead seat surfaces, not the outside edges of the rim. The bead seat is where the tire’s bead rests when mounted.

3. Position a measuring tool

Take a tape measure or caliper and place it across the wheel from one bead seat to the opposite bead seat. Ensure the tool is straight and level across the wheel.

4. Record the measurement

Read the distance in inches (e.g., 8", 9.5"). This value is the wheel width as shown in Illustration “A.”

⚠️ Note: Wheel width is often about 1 inch narrower than the overall rim-to-rim outside measurement, which can cause confusion if measured incorrectly.

Measuring Rear Spacing / Backspacing (Illustration “B”)

1. Lay the wheel face down

Place the wheel on a flat surface with the outer face against the ground and the back (mounting pad side) facing upward.

2. Place a straight edge across the wheel

Lay a straight edge (like a ruler or level) across the top of the wheel’s inner barrel. The straight edge must span fully across both rim lips to give an accurate reference plane.

3. Measure from the mounting pad to the straight edge

Using a tape measure or ruler, measure the vertical distance from the wheel mounting surface pad (the flat area that contacts the hub) straight up to the bottom of the straight edge.

4. Record the measurement

This distance is the rear spacing (backspacing) of the wheel. It determines how far inward the wheel extends toward the suspension and brakes when installed.

⚠️ Important Note:

- Rear spacing/backspacing directly affects brake clearance and suspension fit.

- Together with wheel width and offset, it ensures the wheel clears components and aligns correctly with the fenders.

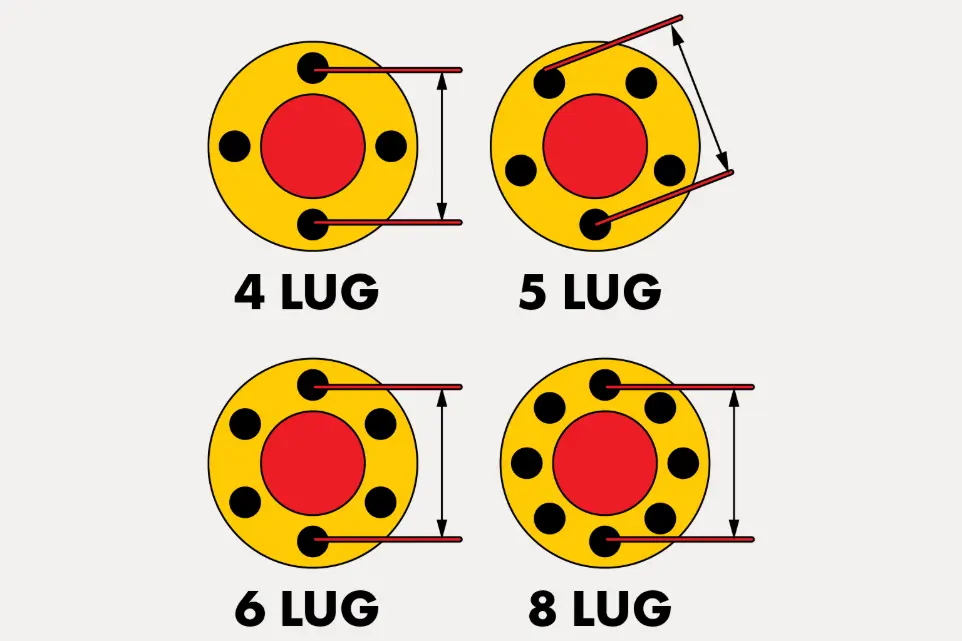

Measuring Wheel Bolt Pattern

🔩 General Notes Before Measuring

- Racing wheels in the U.S. are usually listed in inches for bolt pattern measurements.

- Bolt pattern = number of lugs × circle diameter (e.g., 5×4.5").

- Use a ruler, tape measure, or caliper. Always measure across the wheel hub where lug holes are evenly spaced.

⚙️ 4-Lug Wheels

- Identify two lug holes directly opposite each other.

- Measure from the center of one lug hole to the center of the opposite lug hole.

- The result is the bolt circle diameter (in inches).

- Example: If the distance is 4.00", the pattern is 4×4.00.

⚙️ 5-Lug Wheels

- Because five holes aren’t evenly opposite, you cannot measure straight across.

- Measure from the center of one lug hole to the far outside edge of the lug hole two spaces away (not the next adjacent hole).

- This gives you the bolt circle diameter in inches.

- Example: A measurement of about 4.50" means the pattern is 5×4.5.

⚙️ 6-Lug Wheels

- Choose two lug holes that are directly opposite each other.

- Measure from the center of one hole to the center of the opposite hole.

- Record the distance in inches as the bolt circle diameter.

- Example: If the reading is 5.50", the pattern is 6×5.5.

⚙️ 8-Lug Wheels

- Select two lug holes directly across from one another.

- Measure center to center between the holes.

- The measurement in inches is the bolt circle diameter.

- Example: If you measure 6.50", the pattern is 8×6.5.

✅ Quick Conversion Tip: To switch between systems, remember that 1 inch = 25.4 mm. So, for example, a common 5×114.3 mm pattern is the same as 5×4.5".

⚠️ Important Safety Note

Racing is a dangerous sport. The safety of the driver, crew, and fans depends on having the correct wheels properly fitted. Always ensure the proper wheel sizes and bolt patterns are installed before taking a race car onto the track. Incorrect fitment can cause severe handling issues, mechanical failure, or accidents.